Alcast Company Things To Know Before You Buy

Table of ContentsIndicators on Alcast Company You Need To KnowRumored Buzz on Alcast CompanyAlcast Company Fundamentals ExplainedThings about Alcast CompanyAlcast Company Can Be Fun For EveryoneSome Known Details About Alcast Company

The subtle difference depends on the chemical web content. Chemical Comparison of Cast Light weight aluminum Alloys Silicon promotes castability by decreasing the alloy's melting temperature level and boosting fluidity during spreading. It plays a critical role in enabling complex mold and mildews to be loaded properly. Furthermore, silicon adds to the alloy's toughness and put on resistance, making it valuable in applications where sturdiness is critical, such as auto components and engine parts.It additionally boosts the machinability of the alloy, making it less complicated to refine into finished products. This way, iron adds to the total workability of aluminum alloys. Copper enhances electrical conductivity, making it advantageous in electric applications. It additionally improves corrosion resistance and contributes to the alloy's total toughness.

Manganese contributes to the stamina of aluminum alloys and enhances workability. Magnesium is a light-weight aspect that gives stamina and influence resistance to aluminum alloys.

The Buzz on Alcast Company

It allows the production of light-weight parts with outstanding mechanical residential or commercial properties. Zinc improves the castability of light weight aluminum alloys and aids control the solidification process during casting. It enhances the alloy's toughness and hardness. It is frequently discovered in applications where complex forms and great information are necessary, such as decorative castings and certain vehicle components.

The key thermal conductivity, tensile strength, yield strength, and elongation differ. Select appropriate resources according to the efficiency of the target item generated. Amongst the above alloys, A356 has the highest possible thermal conductivity, and A380 and ADC12 have the lowest. The tensile limit is the opposite. A360 has the best yield strength and the greatest elongation rate.

Alcast Company Can Be Fun For Everyone

In accuracy spreading, 6063 is well-suited for applications where detailed geometries and premium surface area finishes are critical. Instances consist of telecommunication enclosures, where the alloy's exceptional formability permits streamlined and visually pleasing styles while keeping structural integrity. Likewise, in the Lights Solutions industry, precision-cast 6063 elements produce classy and efficient lighting fixtures that need complex forms and excellent thermal efficiency.

It brings about a better surface area coating and better corrosion resistance in A360. Furthermore, the A360 displays remarkable prolongation, making it excellent for facility and thin-walled parts. In accuracy spreading applications, A360 is fit for sectors such as Customer Electronics, Telecommunication, and Power Tools. Its enhanced fluidity enables detailed, high-precision parts like mobile phone cases and communication device housings.

Some Known Incorrect Statements About Alcast Company

Its one-of-a-kind homes make A360 a useful choice for accuracy spreading in these markets, improving product sturdiness and quality. aluminum casting manufacturer. Light weight aluminum alloy 380, or A380, is a commonly made use of spreading alloy with numerous distinct features.

In accuracy spreading, light weight aluminum 413 radiates in the Consumer Electronics and Power Tools industries. It's commonly made use of to craft detailed components like smart device real estates, cam bodies, and power device cases. Its precision is remarkable, with tight resistances as much as 0.01 mm, making sure perfect product setting up. This alloy's premium rust resistance makes it visit our website an exceptional option for outdoor applications, making certain durable, long lasting products in the stated markets.

How Alcast Company can Save You Time, Stress, and Money.

The light weight aluminum alloy you select will considerably affect both the casting process and the residential or commercial properties of the last item. Due to the fact that of this, you must make your decision thoroughly and take an educated technique.

Establishing the most suitable aluminum alloy for your application will certainly mean weighing a wide array of qualities. These comparative alloy qualities follow the North American Pass Away Spreading Organization's standards, and we've split them into two categories. The first classification addresses alloy qualities that impact the manufacturing process. The second covers features influencing the residential or commercial properties of the end product.

Alcast Company - An Overview

The alloy you pick for die casting straight affects numerous aspects of the spreading process, like exactly how easy the alloy is to deal with and if it is prone to casting issues. Hot fracturing, also recognized as solidification breaking, is a regular die casting problem for light weight aluminum alloys that can result in interior or surface-level rips or cracks.

Specific light weight aluminum alloys are extra at risk to hot cracking than others, and your selection must consider this. It can harm both the actors and the die, so you should look for alloys with high anti-soldering residential properties.

Deterioration resistance, which is currently a noteworthy quality of aluminum, can vary considerably from alloy to alloy and is a necessary particular to take into consideration depending on the environmental conditions your product will be exposed to (aluminum foundry). Put on resistance is an additional home frequently sought in aluminum products and can differentiate some alloys

Tia Carrere Then & Now!

Tia Carrere Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Andrew Keegan Then & Now!

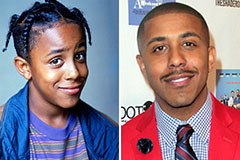

Andrew Keegan Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!